As the field of process spectroscopy grows, so does the number of acronyms associated with the measurement methods. In the last blog post, we discussed the acronyms related to calibration that users may encounter. This blog will give a brief overview of some acronyms that are in frequent use related to Guided Wave analyzers and products. Some of these are specific to Guided Wave, while others are related to the methodology as a whole. The list below is in alphabetical order.

ANSI – American National Standards Institute

The ANSI is a private nonprofit organization that oversees the development of voluntary consensus standards for products, services, processes, systems, and personnel in the United States. The organization also coordinates U.S. standards with international standards so that American products can be used worldwide. These standards ensure that the characteristics and performance of products are consistent, that people use the same definitions and terms, and that products are tested the same way.

ASTM – American Society for Testing and Materials

ASTM International is one of the largest voluntary standards development organizations in the world. They are a source for technical standards for materials, products, systems, and services. ASTM International standards have an important role in the information infrastructure that guides design, manufacturing and trade in the global economy.

ATEX

The European directive 94/9/EC requires that employers must protect employees from explosion risk in areas with explosive atmospheres. Manufacturers and importers must ensure that their products meet specific safety requirements. The goal of ATEX, which gets its name from the directive’s French title Appareils destinés á être utilisés en ATmosphères Explosibles, is to allow free trade of “ATEX” approved equipment within the EU by removing the need for separate testing and documentation for each member state.

CENELEC

CENELEC is the European Committee for Electrotechnical Standardization. This is a non-profit technical organization set up under Belgian law and composed of the National Electrotechnical Committees of 30 European countries. CENELEC’s mission is to prepare voluntary electrotechnical standards that help develop the Single European Market/European Economic Area for electrical and electronic goods and services removing barriers to trade, creating new markets and cutting compliance costs.

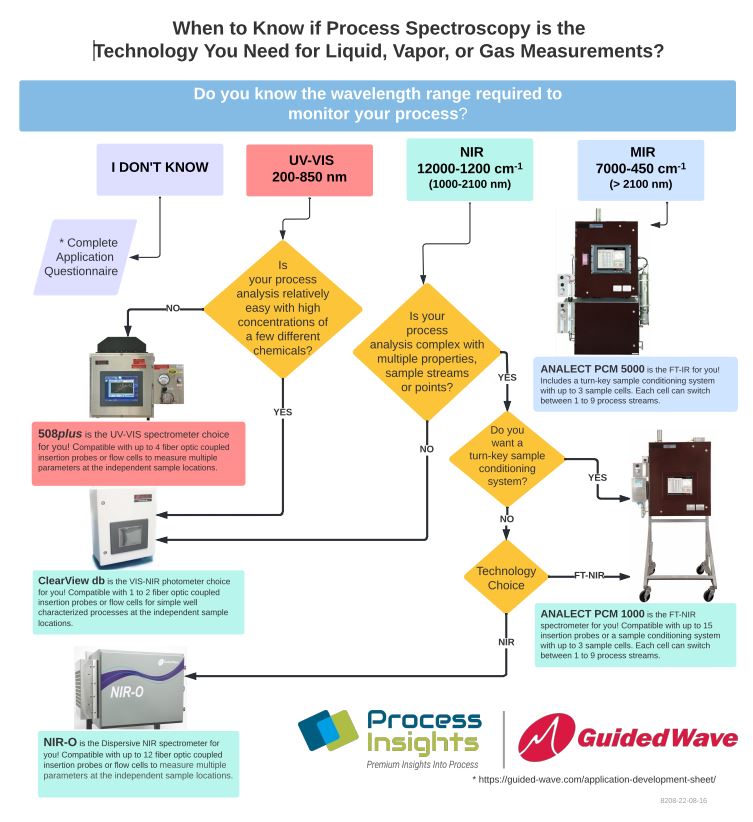

FT-NIR

Fourier transform spectroscopy is a measurement technique whereby spectra are collected based on time-domain measurements of the electromagnetic radiation. It can be applied to a variety of types of spectroscopy, including Near-Infrared spectroscopy (see NIR below).

ISO

ISO is an international-standard-setting body composed of representatives from various national standards organizations. The organization promulgates world-wide proprietary industrial and commercial standards. ISO is a network of the national standards institutes of 157 countries, one member per country, with a Central Secretariat in Geneva, Switzerland, that coordinates the system.

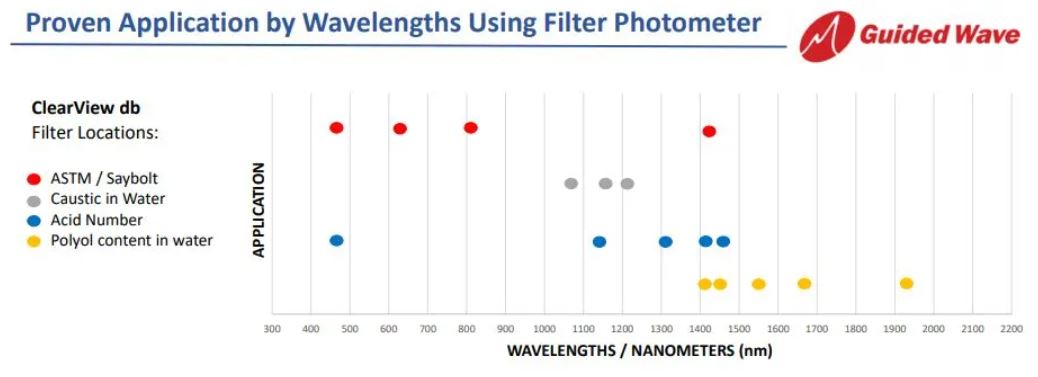

NIR

Near-Infrared or NIR is a region of the electromagnetic spectrum from about 750nm to 2600nm. Near Infrared Spectroscopy is the technique of using a sample’s NIR absorbance characteristics to predict parameters of interest. Molecules containing C-H, O-H, and N-H bonds absorb NIR radiation in specific regions or at specific wavelengths. These absorbance’s can then be used in a qualitative or quantitative measurement. NIR spectroscopy is widely used in both process and laboratory measurements across many industries (chemical, refining, pharmaceutical, polymer, semi- conductor, agricultural).

NIST

The National Institute of Standards and Technology (NIST), previously known as the National Bureau of Standards (NBS), is a non-regulatory agency of the United States Department of Commerce. The institute’s mission is to promote U.S. innovation and industrial competitiveness by advancing measurement science, standards, and technology in ways that enhance economic security and improve quality of life.

PAT

Process Analytical Technology (PAT) has been defined by the United States Food and Drug Administration (FDA) as a mechanism to design, analyze, and control pharmaceutical manufacturing processes through the measurement of critical process parameters and quality attributes. While this term was initially defined in relation to the pharmaceutical industry, the concepts and methods can be extended to other industries.

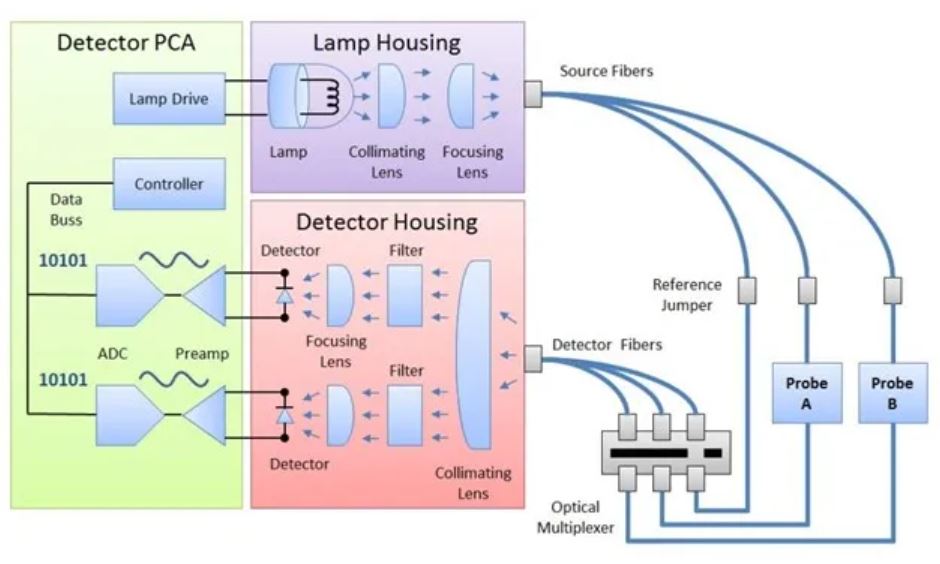

SST

The Single-Sided Transmission (SST) Probe is a rugged and reliable sample probe that is ideal for continuous process monitoring applications. SST means that light passes through the sample region only once. In contrast, transflectance probes pass twice, being reflected from the far end. The SST probe can be easily installed in a pipe or reactor through a single access port and works with any Guided Wave single-fiber spectrometer or photometer. Optional accessories make it easy to adapt the SST Probe to different kinds of process installations.

UV/VIS

UV/VIS spectroscopy is the measurement of the wavelength and intensity of absorption of ultraviolet and visible light by a sample. Ultraviolet and visible light are energetic enough to promote outer electrons to higher energy levels. UV/VIS spectroscopy is usually applied to molecules and inorganic ions or complexes in solution. The spectra have broad features that are of limited use for sample identification but are very useful for quantitative measurements. The concentration of an analyte in solution can be determined by measuring the absorbance at some wavelength and applying the Beer-Lambert Law.

Calibration Acronyms

ANSI- American National Standards Institute

ASTM- American Society for Testing and Materials

ATEX- Atmosphéres Explosibles (French)

CENELEC- European Committee for Electrotechnical Standardization

CIE – International Commission on Illumination

FT- NIR- Fourier Transform Near-infrared

ISO- International Organization for Standardization

NIR – Near-Infrared

NIST- National Institute of Standards and Technology

PAT- Process Analytical Technology

SST- Single Sided Transmission Probe

UV/VIS- Ultraviolet / Visible