Building a Starter Chemometric Calibration

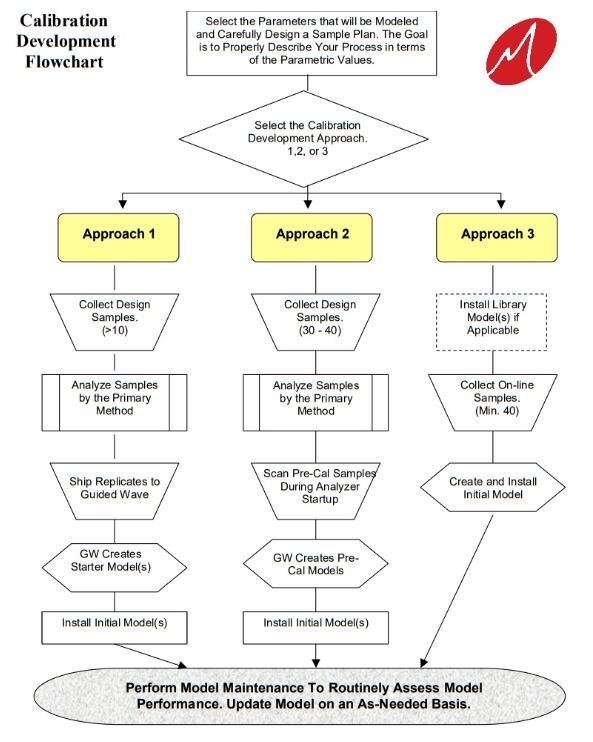

The initial calibration is typically referred to as a starter model. The difficulty of building a successful calibration depends on the complexity of the process stream and the quality of the lab reference data. To ensure customer success, we have three recommended procedures for collecting, organizing, and analyzing the data to build a starter chemometric model.

Periodic Chemometric Model Maintenance

Once an initial model is developed, it must be periodically validated against QC lab results. We recommend the Delta Chart method for evaluating online chemometric model performance. A Delta chart created by plotting the comparative difference between a predicted value and a matching laboratory result. By analyzing the delta chart, the chemometric model can be further improved. The data can also be used for periodic model maintenance.

Need Help with Chemometric Modeling?

We specialize in providing remote support and training in chemometric modeling. In addition, we sell starter models for many NIR process monitoring applications.