NIR Measurements in Polyurethanes

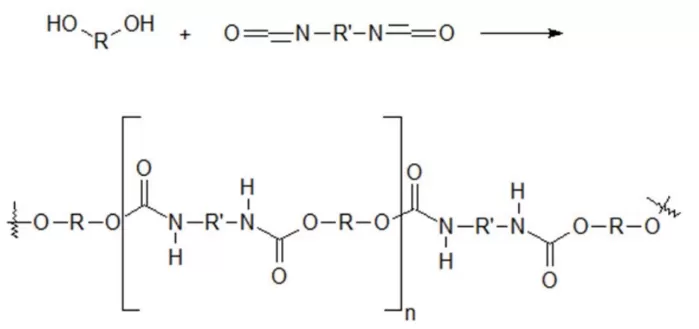

Polyurethanes are one of the most versatile polymers available. Polyurethanes can be a found in liquid coatings and paints, elastomers, rigid insulation, soft flexible foam, elastic fiber, and many other materials. Today, polyurethanes can be found in virtually everything we touch our desks, chairs, cars, clothes, footwear, appliances, beds, the insulation in our walls, roof and moldings on our homes. Polyurethanes are made by reacting diisocyanates with dialcohols (Figure 1).

Figure 1

Many aspects of polyurethane production can be measured using Near infrared (NIR) spectroscopy. This application note will describe the potential uses of Guided Wave hardware and software tools for key measurements in polyurethane production using fiber optic based NIR spectroscopy. Guided Wave analyzer systems use fiber optics to allow the sample probe to be located in remote locations away from the spectrometer itself. NIR spectroscopic methods can be applied in real time directly in process monitoring or as laboratory procedures. In either case NIR is a time and money saving alternative to traditional methods. NIR also offers the benefit of increased safety over traditional methods.

Using Process NIR spectroscopy to Measure Polyurethanes

The NIR region of the electromagnetic spectrum has absorbance bands resulting from overtones and combinations of the C-H, O-H, and N-H fundamental bands in the mid infrared. Typically the NIR spectra of a series of samples of standards are used to generate a quantitative model that will be used to measure the composition (or property) in future samples based only on the sample’s NIR spectrum. The initial model development step is the optimization of data pre-processing to improve model accuracy. These pre-processing steps are typically in the form of baseline correction or derivative calculation, but may include more complex calculations. The pre-processed spectra and concentration or property data are then submitted to the Unscrambler® software and a calibration model is developed using PLS regression methodology. For a discussion of PLS and other multivariate calibration techniques please see Martens & Naes1 and ASTM E16552.

Polyurethane Raw Materials

Polyurethanes contain the repeating unit:

Polyurethanes are produced by a reaction of diisocyanates with dialcohols. As a simplified example of raw material measurement potential, the spectra of ortho and para tolylisocyanate were measured using both 2 and 10 mm path probes. The 10 mm path probe produces spectral data in the 1000 – 1600 nm region that would be suitable for quantitative measurements while the 2 mm path spectra have useful information in the extended NIR region of 1600 – 2000 nm. Which region proves to be most useful will depend on the property being measured and on the other materials present in the reaction. Figure 2 shows the isocyanate spectra using the 10 mm path probe in comparison to ortho and para chlorotoluene. This shows the isocyanate peak at approximately 1490 nm and some possible distinction between the isomers of the isocyanate. Figure 3 shows the spectra of the same materials using the 2 mm path probe extending the wavelength range out to 2050 nm. These spectra show similar distinctions, with a band due to the isocyante seen at approximately 1870 nm.

Figure 2

Figure 3

When considering final product measurements, polyurethanes can really be considered an amide or an ester of carbonic acid (carbamate). To examine this functional group, the spectrum of methyl and phenyl carbamate were measured. Figures 4 and 5 show the spectra of neat methyl carbamate, and phenyl carbamate at 10% concentration in acetone. Again, two pathlengths are used to show data in both the short and the long wavelength NIR regions.

The peaks arising from the carbamate are seen at 1475 nm and 1960 nm in the 10 mm and 2 mm pathlength spectra respectively. The wavelength separation between the isocyanate bands and the carbonate bands should be sufficient to allow quantitative measurements to be made when both are present.

Figure 4

Figure 5

Conclusion – OH number can be Monitoried by NIR

The measurement of OH number of polyols using NIR spectroscopy has been shown in earlier studies to be both fast and reliable utilizing the Guided Wave hardware and software tools. The data shown here indicates that additional measurements in polyurethane systems are feasible. The use of remote spectroscopic measurement methods provides analyses in real time and minimizes the need for performing laboratory measurements. These methods can be applied in reactor systems for control of important properties during the reaction and to determine the endpoint of the reaction thus adding to the value and cost savings. The accuracy of any such measurements would need to be studied in greater detail. For more detailed information regarding either further feasibility studies or system specifications please contact a Guided Wave sales or technical specialist.

References

- H. Martens, T. Naes

- Multivariate Calibration, John Wiley & Sons, 1989.

Questions? We’re here to help.

Support: info@process-insights.com

TERMS AND CONDITIONS

TERMS AND CONDITIONS FOR SERVICE

SELLERS AGREEMENT

DATA PROTECTION

FRAUD ALERT

CHINESE

SITE MAP

-

Technology

Products

Blog

Applications

Application Questionnaire

ISO 9001 Certificates

Copyright © 2022 Process Insights, Inc. All Rights Reserved.