On-Line Monitoring of Epoxy Value with a ClearView® db Photometer

The purpose of this application note is to demonstrate how to measure epoxy value and starting liquid resin content with the two-channel ClearView db photometer and fiber optic insertion probes with simple, easy-to-maintain, linear calibrations.

The NIR peak at 2208 nm is traditionally used to measure epoxy value. However, this intense peak requires a narrow optical path (2 mm). Also, the basic liquid resin starting material is a spectral interferent, requiring more sophisticated(multivariate) calibration methods. A full spectrum diode array NIR spectrometer was used to measure the NIR spectra of 13 samples in a 5 mm cuvette at 190° C.

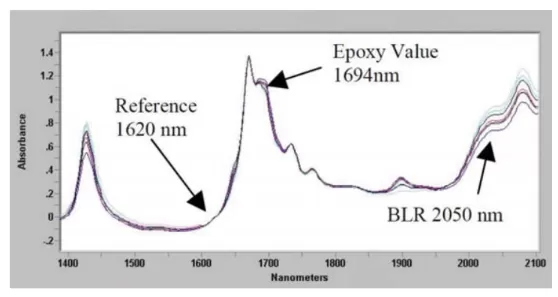

Figure 1 NIR Spectra of Polymer Resin

Feasibility Study: Determination of Epoxy Value by NIR Process Spectroscopy

The resulting spectra are shown in Figure 1 for samples ranging in epoxy value from 0.037 to 0.182. Epoxy value can easily be measured in the NIR range using a peak wavelength at 1694 nm and a reference wavelength at 1620 nm. The measurement of liquid resin content is readily measured at 2050 nm. The resulting calibration for the epoxy value is linear, as shown in Figure 2, with an average error of 0.004%. Linearity extends to epoxy values of 0.5 in a more recent study. The basic liquid resin content measured at 2050 nm is shown to linearly decrease with increasing epoxy value in Figure 3, as expected.

Figure 2 NIR Calibration results for Epoxy Value

Figure 3 NIR Calibration results for basic liquid resin

Conclusion- NIR Process Photometer can easily Monitor the Epoxy Reaction

These results suggest that a ClearView db dual-beam filter photometer with three wavelengths can easily monitor the epoxy reaction. The ClearView db can accommodate up to six separate wavelengths and can be used to monitor two probes (sample locations) simultaneously. The dual probe capability provided for the lowest cost-per-point available.

Questions? We’re here to help.

Support: info@process-insights.com

TERMS AND CONDITIONS

TERMS AND CONDITIONS FOR SERVICE

SELLERS AGREEMENT

DATA PROTECTION

FRAUD ALERT

CHINESE

SITE MAP

-

Technology

Products

Blog

Applications

Application Questionnaire

ISO 9001 Certificates

Copyright © 2022 Process Insights, Inc. All Rights Reserved.