Process Fiber vs. Traditional Process Fiber Optic Cables

Often when installing a complete analysis system; spectrometer, fiber optic cables, and sample interfaces, the noise contribution of the fiber optic cable is overlooked. For some applications simply finding the least expensive fiber optic cable is enough. However, many applications require more precision to reduce noise and meet the application requirements. For applications requiring a thermally stable process fiber, Guided Wave offers a patented fiber optic cable design shown in the image below. The black Silicone Buffer and Inner Tefzel™ dramatically reduce the effects of naturally occurring temperature variations.

Signal stability and low noise in remote spectroscopy depend upon fiber optics with high transmission. The transmission must be affected very little by environmental influences such as temperature, vibration, and ambient light levels. From a patented fiber design to our emphasis on high-quality materials, Guided Wave spectroscopic grade fiber optic cable is designed for the highest performance in transmission efficiency and durability. A polyimide coating and a patented silicone-based buffer protect the fiber as well.

For critical spectroscopic measurements, Guided Wave’s engineers developed a special formulation of thermally stable 500-micron and 600-micron near-infrared (NIR) fiber optic cable. The 500-micron fiber core was optimized for use with Guided Wave’s NIR-O Full Spectrum spectrometer and the ClearView db (dual beam) photometer but can also be used with any other fiber optic-based analyzer brands. The 600-micron fiber core was specifically engineered by Guided Wave for Bruker FT-NIR users who need a thermally stable fiber optic cable. Using Guided Wave’s high optical efficiency insertion probes and flow cells coupled to this 600-micron fiber enable Bruker users to achieve the highest performance under process conditions.

Proving the Value:

Thermally Stable Fiber Optics – NIR readings during 30-45 C○ Thermal Cycling

To prove the value of Guided Wave’s industry leading NIR fiber, a 50m spool of thermally stable fiber optic cable and a 50m spool of a competitor’s brand fiber optic cable were loaded into the environmental chamber. Both fibers were then connected to a NIR-O Full Spectrum Analyzer. After referencing both fibers, a thermal cycling routine on the oven was performed overnight (30-45C○ two cycles). Spectra of each fiber spool were collected once every 10 minutes.

Figure 2: Fiber spools loaded into environmental oven.

Figure 3: Thermal Cycling at 30-45 C○

Reducing Signal Drift Due to Natural Thermal Variation

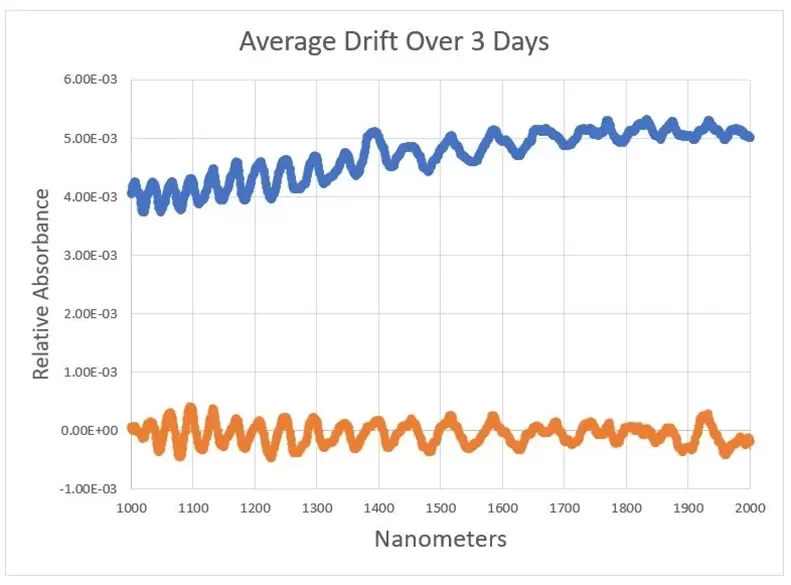

The jacketing design of the thermally stable NIR fiber optic cable reduces drift in the analyzer system. Fifty meters of both the Guided Wave thermally stable fiber and the competitor’s fiber was spooled out on the factory floor and connected to a NIR-O Full Spectrum Analyzer, a zero or reference was collected. The analyzer was then scheduled to collect one spectrum on each fiber optic cable once a minute over 3 days.

Figure 4: Both brands of fiber optic cable unspooled on the factory floor.

Figure 5: Seventy-two hours of drift data.

Figure 5 shows the average of all the spectra collected over the 3 days. The blue line which drifted ~4 mAu, is the competitor’s traditional fiber. The orange line which stayed close to zero is the thermally stable fiber.

Applications Requiring a Thermally Stable Process Fiber

In many applications, such as monitoring Saybolt Color or the Cetane value of Diesel 4 mAu of drift is acceptable and would contribute less than a 2% deviation in the NIR reading. However, for critical measurements near the lower detection limits of the spectrometer, Guided Wave recommends the premium thermally stable fiber optic cable. For example, refinery measurements such as PIONA (Paraffins, Isoparaffins, Olefins, Napthenes, Aromatics) requires the lowest amount of noise for NIR to distinguish between n-paraffins and isoparaffins.

Simulating the Thermal Variation of a Passing Cloud

Fifty meters of both the thermally stable and the competitor’s traditional fiber optic cable were spooled onto the shop floor. The fiber was then allowed to warm up over several hours. In the noonday sun, a wooden board was used to provide partial shade to each fiber spool. The purpose of this test was to simulate the thermal variation of a passing cloud or other sources of shade that can alter the data collected by a NIR analyzer.

It is expected that the thermal variations/noise would be higher for fiber installed in a bare cable tray opposed to the inside of a conduit. Figure 7 indicates that the thermally stable fiber showed no deviation due to the shade. Whereas, the competitor’s fiber had a ~1 mAu bias within 60 seconds when the shade is applied. When the shade was removed the competitor’s, fiber drifted back towards its previous levels.

Figure 6: Official Guided Wave cornhole board acting as a sunshade.

Figure 7: Influence of sun vs. shade on both brands of fiber optic cabling.

Need a Higher Level of Excellence in Your NIR Process Monitoring?

For optimal system performance and savings, it’s important to properly select the optical fiber cables that will best match the spectroscopic analyzer system. Keep in mind the optical wavelength range, environmental installation conditions, required signal transmission distance, fiber diameter, and installation requirements. Contact Guided Wave for pricing and availability of our thermally stable near-infrared fiber optic cables and industry-leading optical efficiency sample interfaces.

To help protect your investment follow the installation guidelines in the Fiber Optic Cable Instructions Technical Service Bulletin. For further questions call the experts at Guided Wave +1 916 638-4944.

Questions? We’re here to help.

Support: info@process-insights.com

TERMS AND CONDITIONS

TERMS AND CONDITIONS FOR SERVICE

SELLERS AGREEMENT

DATA PROTECTION

FRAUD ALERT

CHINESE

SITE MAP

-

Technology

Products

Blog

Applications

Application Questionnaire

ISO 9001 Certificates

Copyright © 2022 Process Insights, Inc. All Rights Reserved.