How Does Process Spectroscopy Work?

NIRS or Near-Infrared Process Spectroscopy is the process of transmitting light through a sample, portions of the light are absorbed by various compounds in the sample, with the remaining transmitted light being sent to either a Dispersive Grating spectrometer (DG-NIR) or a Fourier transforms spectrometer for analysis. For practical purposes, the difference between FT-NIR and DG-NIR analyzers only lies in the underlying technology. Both methods produce comparable readings which a technician or area manager can use to make informed decisions. The spectrometer measures the difference between the pure spectrum of the light source and the light which passed through the sample, resulting in an absorbance spectrum. By varying the known concentration of specific chemicals between samples a calibration curve can be generated using chemometrics.

What is NIR Process Spectroscopy used for in the Petrochemical Industry

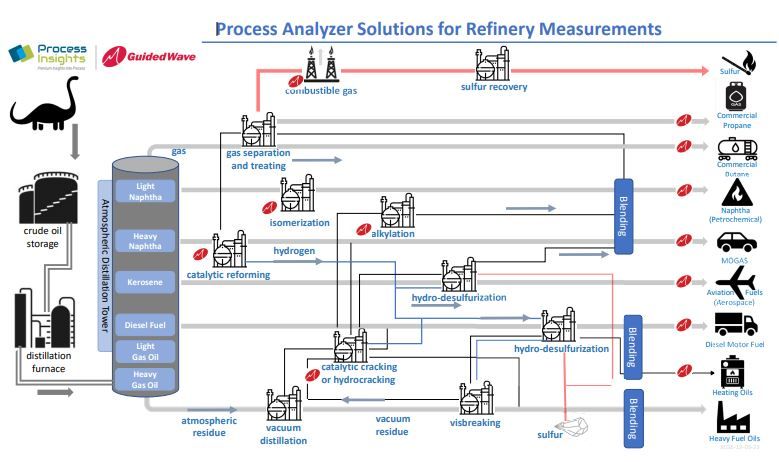

Near-Infrared (NIR) spectroscopy is used to monitor the hydrocarbon composition of various streams in the Petrochemical and Refining Industries. As shown in the above infographic, a sample interface can be installed in each processing stage of a refinery to provide real-time data and actionable information. At each stage of the refinery, NIR spectroscopy is used to monitor specific traits such as the Research Octane Rating, Benzene content, and Butane content.

What is Fuel Blending?

According to the US Energy Information Administration fuel blending is the process of mixing different fractions of crude oil distillations to produce specific grades of gasoline or diesel fuel. Additionally, various amounts of ethanol, a common biofuel additive for gasoline, and other additives can be included in the blending process. By homogenizing the various chemicals together, the desired octane rating or required emission standards for the fuel can be achieved.