Benzene in Gasoline

Benzene is a naturally occurring compound in crude oil and a very useful chemical solvent and feedstock. Unfortunately, it can be a significant health risk and is therefore environmentally regulated in many common products especially gasoline. Thus strict limits are put on the concentration and accurate measurements are required. The traditional analytical method for measuring benzene is gas chromatography (GC), which is time and labor intensive. This note will discuss the use of Guided Wave hardware and software tools for the measurement of % Benzene in fuel products using fiber optic based, Near-Infrared (NIR) spectroscopy. NIR can be applied in real time directly in process monitoring or as a laboratory procedure. In either case NIR is a time and money saving alternative to traditional methods.

The NIR region of the electromagnetic spectrum allows the use of the overtone and combination bands of the C-H, O-H, and N-H fundamentals. By measuring the NIR spectra of a series of fuel samples of known benzene concentration, a quantitative model can be developed which will allow the measurement of benzene in future samples based only on their NIR spectrum. Guided Wave analyzer systems use fiber optics to allow the sample probe to be located in remote locations away from the spectrometer itself.

Experimental – Percentage of Benzene in Gasoline

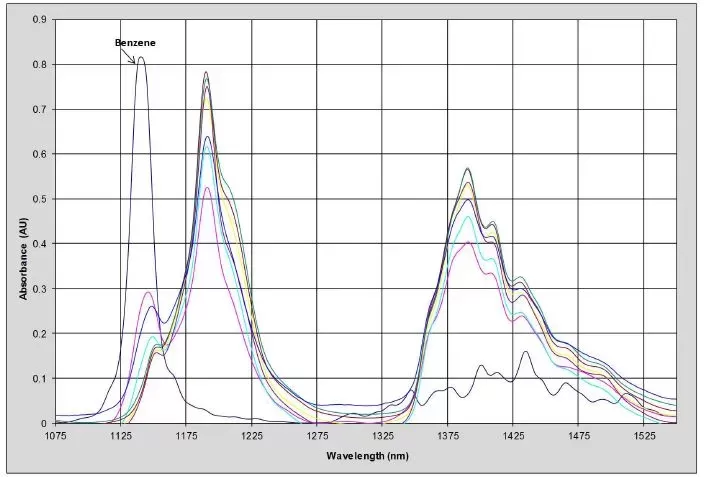

The NIR spectra of a group of 150 different process gasoline samples with known benzene concentration ranging from 0.2 to 6.0% were measured between 1000 and 1600 nm using a Guided Wave NIR Spectrometer. Figure 1 shows the absorbance spectrum of pure benzene along with representative spectra of gasoline samples collected using an on-line process probe with a 1 cm pathlength. For this application, data preprocessing consisted of a simple 2-point baseline correction to remove any offset.

Figure 1: NIR Specta of Pure Benzene and Gasoline Samples

The spectra and concentration data were submitted to the Unscrambler™ software and a calibration model was developed using PLS regression methodology. For a discussion of PLS and other multivariate calibration techniques see Martens and Naes 1 and ASTM E16552.

Results – Prediction of Benzene Concentrations

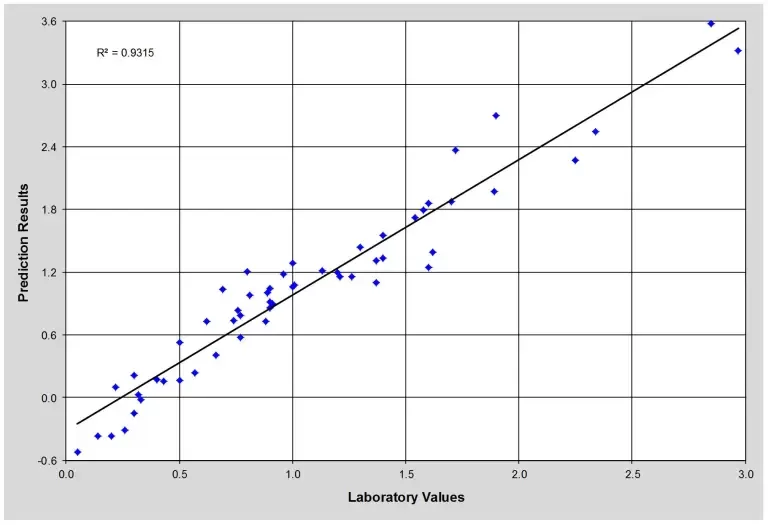

The model was used to predict benzene concentrations using an in-situ probe inserted in a process stream measuring in real time. The results for this are shown in Figure 2 as a scatter plot and in Figure 3 as a trend plot. The model produced a prediction RMSEP (root mean square error of prediction) of 0.30% benzene. This is in good agreement with the accuracy of the standard laboratory method.

Figure 2: Prediction of Low Benzene Levels

Figure 3: Trend Plot Lab vs NIR % Benzene

Conclusion

The measurement of benzene in gasoline using NIR spectroscopy is both fast and reliable utilizing the Guided Wave hardware and software tools as described here. This method minimizes the need for laboratory sample collection. Results are available in real-time (seconds) for multiple parameters in complex streams. For more detailed information regarding system specifications please contact a Guided Wave sales or technical specialist.

References

- H. Martens, T. Naes, Multivariate Calibration, John Wiley & Sons, 1989.

- ASTM E1655 Standard Practices for Infrared, Multivariate, Quantitative Analysis.

Questions? We’re here to help.

Support: info@process-insights.com

TERMS AND CONDITIONS

TERMS AND CONDITIONS FOR SERVICE

SELLERS AGREEMENT

DATA PROTECTION

FRAUD ALERT

CHINESE

SITE MAP

-

Technology

Products

Blog

Applications

Application Questionnaire

ISO 9001 Certificates

Copyright © 2022 Process Insights, Inc. All Rights Reserved.