Fiber Optic Cable Instructions

High Performance Fiber Optic Cable for Spectroscopy

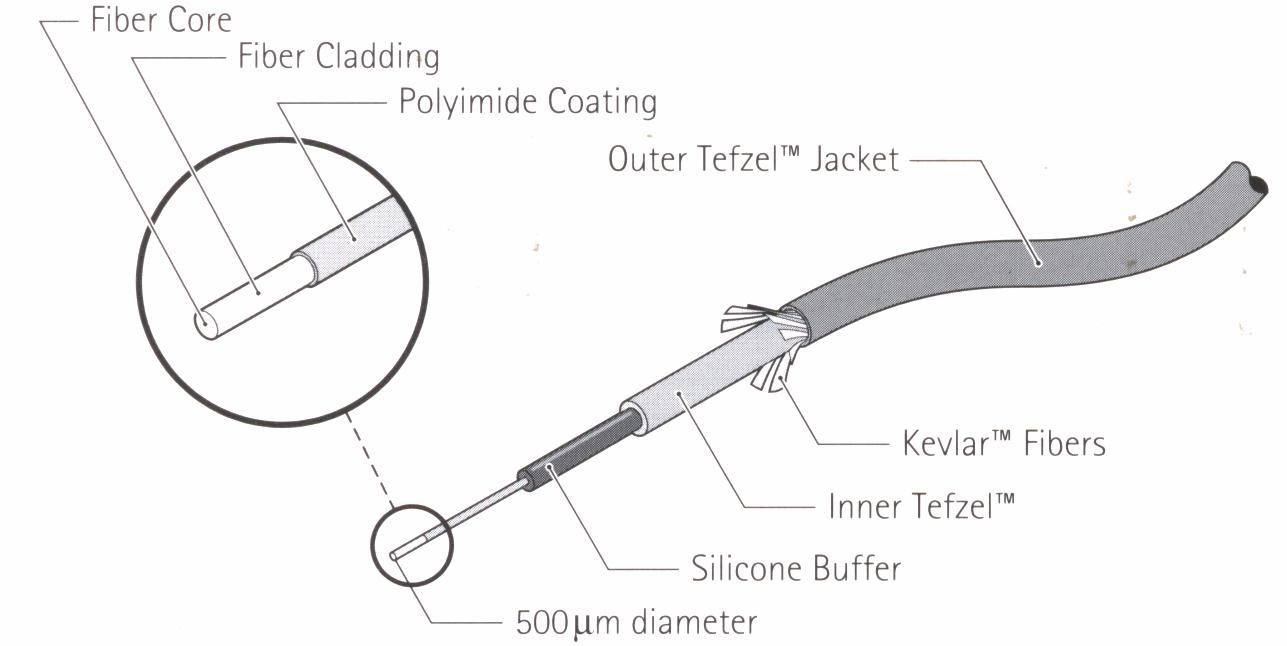

Ultra high-grade and optically efficient, our durable fiber optic cable incorporates the best available materials when it comes to jacketing, coatings, cladding, and core purity. Although it is very durable proper handling is crucial to avoid damaging the cable. Follow the installation guidelines in this Technical Service Bulletin to help ensure optimal performance from your Guided Wave Thermally Stable Process fiber optic cables.

Cable Pulling

To install the cable into cable trays or conduit, hand pulling is permitted for short distances. Since the cable is relatively stiff, it can even be fed (i.e. pushed) from the reel into the conduit. If the conduit is clean, 10 to 20 meter (30 to 60 feet) lengths can be installed in this manner. Avoid any looping or kinking of the cable and do not force the cable.

The most common installation method uses a cable-pull tool. Secure the cable with a cable-puller that pulls on 4 or more inches of the jacket only (100 to 200 mm). Do not pull on the connector!

For terminated cable, leave the vinyl protector in place and then wrap tape (e.g. electrical tape) around the connector body to provide a smooth end. An alternative approach is to use a wooden boat contoured to seat the connector with a stringer attached to the front end of the boat and a cable-puller attached to the back end of the boat. Several centimeters of travel should be allowed within the boat for the connector.

In either pulling method, the objective is to off-load tensile forces from the connector and evenly distribute tensile forces on the cable jacket. Maximum tensile force should be limited to 50 kg (110 lbs.).

Conduit or cable bend radii should not be less than 15 cm (6 inches). Sharp corners and sharp edges must be avoided in either conduit or cable trays.

Dereeling

After the cable is wound on the reel, a ‘set’ is developed in the cable. This set has a radial and a torsional component. When the cable is dereeled, (removed from the reel) it has a tendency to form loops and the cable end may tend to rotate about its’ axis if the cable removal process is different from the winding process. Therefore, DEREEL THE CABLE BY ‘PULLING’ THE CABLE FROM THE REEL AS THE REEL IS ROTATED. A friction clutch (10-20 lbs, 5-10 kg) on the dereeler is desirable for long cables. This requires a spindle through the hub of the reel to rotate it.

Fiber and Probe Installation Guidelines

- Guided Wave recommends that the optical fiber run through a cable tray or a conduit. This provides both mechanical and environmental protection for the fiber.

- A suitable watertight flexible conduit may be used to connect the probe to the rigid conduit. Enough slack must be left in the flexible conduit to allow for the motion of the probe during referencing, cleaning, or removal from the process line.

- If the fiber is run unprotected a protective sleeve or coupling must be installed on the probe to protect the SMA/bulkhead connector from the elements.

- All junction boxes that will hold extra fiber (standard 500″m core diameter) must be at least 30cm (12 inches) across. FIBER SHOULD NOT BE SUBJECTED TO A BEND RADIUS OF LESS THAN 15cm (6 INCHES). However, a smaller radius may be acceptable for fiber with a smaller core diameter.

- Probes require periodic service and the fiber optic cable must allow enough of a service loop to allow servicing without removal of the cable from the probe.

- Fiber optic cable runs should be sized so that you have 1 to 2 meters extra on each end to allow for service. Store the extra fiber in junction boxes.

- When not in use, fiber connectors must be covered by the small dust caps provided. Do not remove these caps until the fiber is installed.

- Fiber conduit must be sized so that it will provide adequate clearance to pull terminated cables.

- The fiber optic cables are an integral part of the spectrometer. The terminations must be rigorously inspected. Any flaws will degrade system performance. Thus, Guided Wave recommends that you purchase your fiber pre-terminated.

Free Standing Cables

Cables attached along building walls, or piping should be secured every 1 to 2 meters (3 to 6 feet) for both vertical and/or horizontal installations. The cable should be buffered from cable ties by a soft elastomer grommet or laid through an 8 to 10 mm (0.3 to 0.4 inch) diameter, 50 to 75 mm (2 to 3 inch) long, split soft tube. A cable drop of 15 to 20 cm (6 to 8 inch) per 1 to 2 meters (3 to 6 feet) horizontal support provides the best buffering. For aerial installations, a guide wire should be used for support.

Note

The cable is capable of supporting itself over 100 meters (330 feet) or more, but it will be overly sensitive to environmental effects. Attachment to the guide wire is the same as free standing cables except a soft adhesive (e.g. RTV silicone) should be used to prevent the drop of the cable from shifting between tie points.

Cable Relaxation

Once the cable is installed, it should be checked for sharp bends, loops, or crimping. If the installation is done properly, the cable will then require time to relax. At a 25 °C (77 °F) ambient, this will require 1 to 2 days; however, if the ambient temperature is colder, more time will be required.

Environmental Effects

The environment influences performance. Low temperature can affect throughput of the cable, particularly below –60 °C (-76 °F) where a phase change of the buffer material occurs.

Thin layering of ice (aerial installation) has a slight effect on the throughput while freezing water in underground ducts can cause permanent damage.

Hydrogen rich environments cause optical detail to be generated in the NIR spectral range. The hydrogen gas permeates the glass filament and causes detailed spectral bands to appear. This phenomenon appears to be only cause by hydrogen.

Vibration

Vibration does not affect the fiber optic cable unless the cable is in tension or longitudinal compression. If such conditions cannot be avoided, then shield the cable from contact with surfaces subject to severe vibration.

Understanding Jacketed Fiber Optic Cable

Guided Wave’s jacketed single strand fiber optic cable has unique handling requirements. These requirements reflect the unique nature of a glass filament. Specifically, a glass filament has very high tensile strength but very low shear strength.

As a wave guide, the walls of the filament become sensitive to applied pressure resulting in localized attenuation over broad spectral ranges or selected narrow spectral ranges depending on the periodicity of the pressure along the fiber axis.

The fiber optic cable is constructed of a glass fiber with a soft resilient material adjacent to the wave guide, followed by harder materials. Longitudinal tensile members are also added to off load tensile forces from the glass fiber.

Questions? We’re here to help.

Support: info@process-insights.com

TERMS AND CONDITIONS

TERMS AND CONDITIONS FOR SERVICE

SELLERS AGREEMENT

DATA PROTECTION

FRAUD ALERT

CHINESE

SITE MAP

-

Technology

Products

Blog

Applications

Application Questionnaire

ISO 9001 Certificates

Copyright © 2022 Process Insights, Inc. All Rights Reserved.