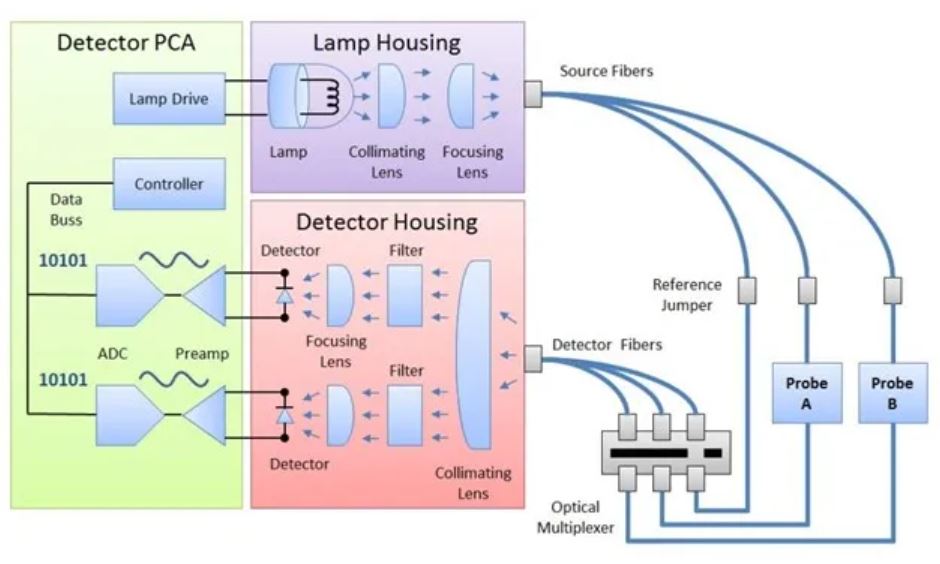

SMS provides an advantage over other systems. For example, with FT-NIR analyzers, validation is often done using external fluids (i.e., Pentane and Toluene) which may not be readily available and are an expensive consumable. With a Guided Wave NIR-O analyzer the SMS validation system is simple and requires no maintenance or consumables. Using SMS there is no need to interrupt the other channel operation. It provides automatic and continuous analyzer validation according to ASTM methodology.

Stability Monitoring System Technology Ensures Validated Results

Stability Monitoring System Technology Ensures Validated Results

Guided Wave News / By

Continuous, Simple, No Consumables

SMS Validation Detects Changes in Performance

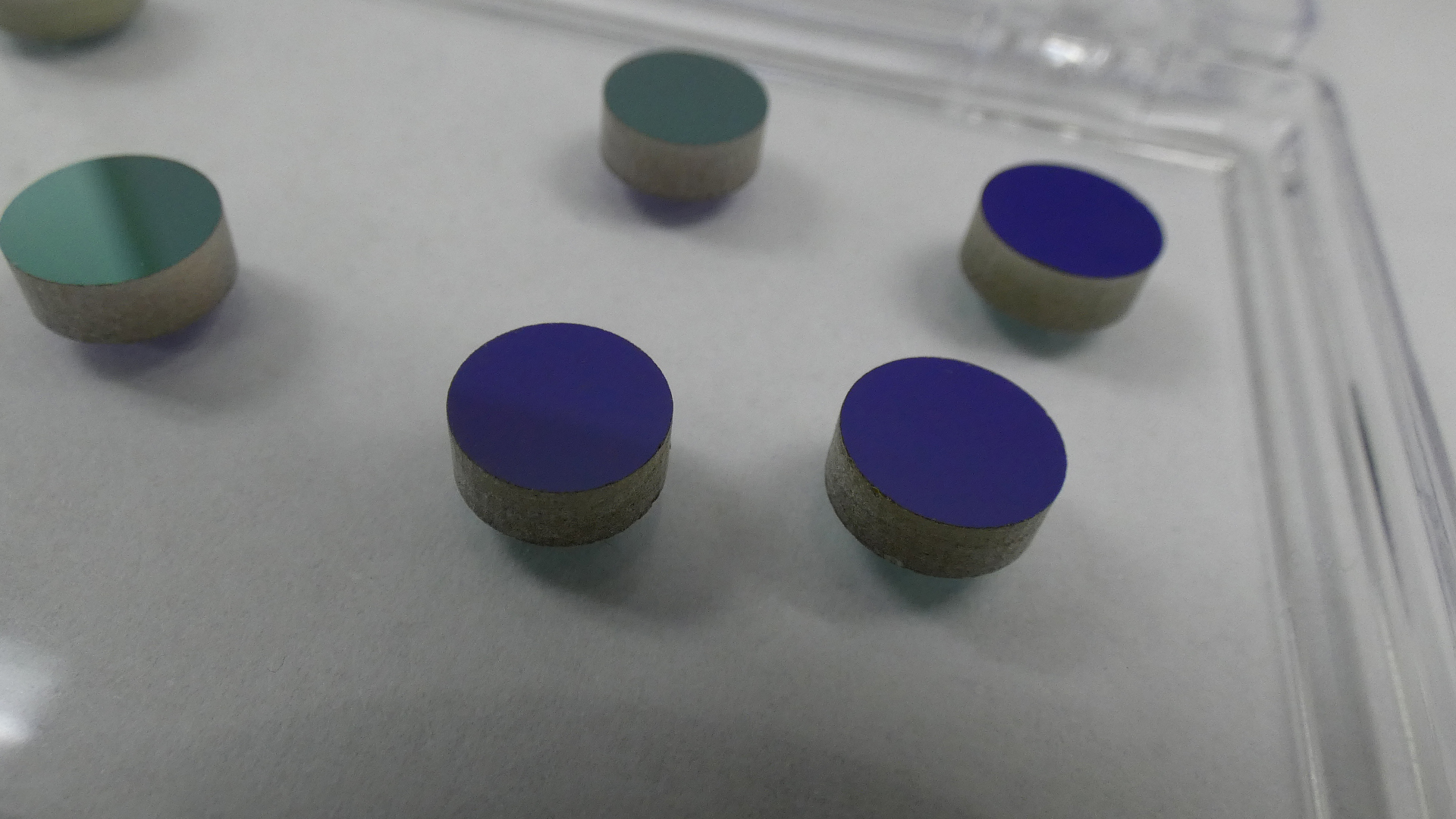

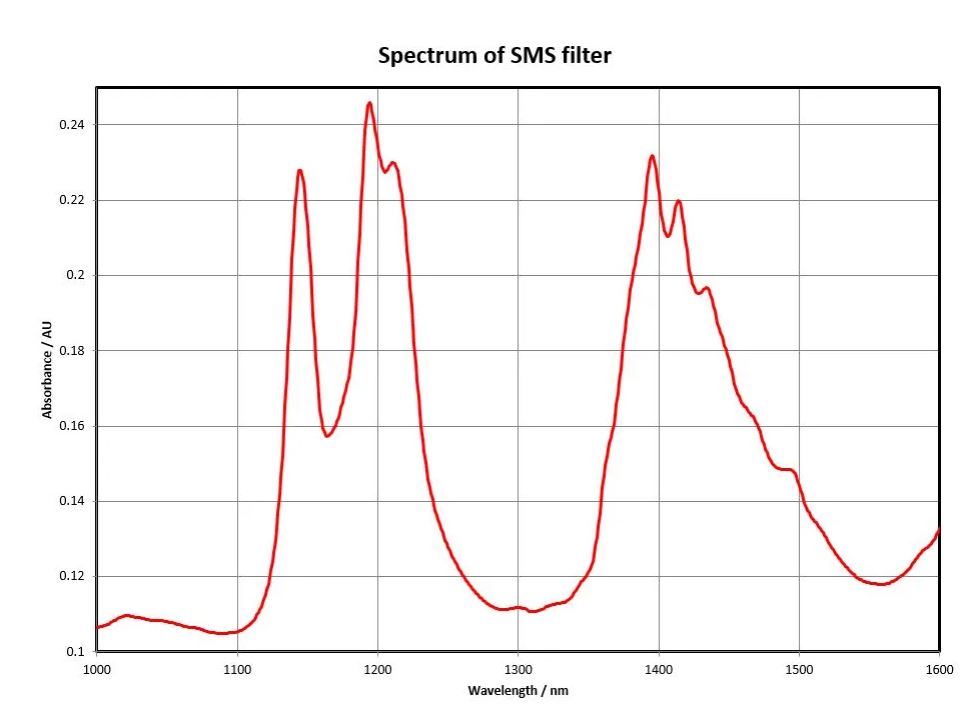

The performance tests identified in the ASTM D-6122 validation practice are diagnostics that can be used to detect changes in analyzer performance. This validation provides assurance that the measurement produced by the analyzer is a result of equipment that is operating properly. Since this is a hands-off procedure, it can be conducted in the background with no human intervention. The validation is done with an internal filter having a characteristic spectral signature. There are no liquids or other external sampling modes that are necessary. Everything is contained inside the

NIR-O analyzer enclosure and all SMS related materials are completely non-hazardous. This topic is addressed in ASTM practice D-6122-19 under

instrument performance tests. The ASTM practice provides a set of criteria for establishing baseline analyzer performance validation. Three levels of hardware testing are established:

Level 0 – When Level 0 – Tests the analyzer hardware’s capability to generate a consistent spectrum. This is accomplished by measuring photometric noise, baseline stability, spectral resolution, photometric linearity, and wavelength stability.

Level A – Tests compare key parts of the spectral data with historical data to identify deviations.

Level B – Tests and monitors the instrument performance for deviations that affect the system calibration models.

Built-in SMS Provides Peace of Mind

Guided Wave’s SMS operation is seamlessly integrated into the OmniView control software for NIR-O. SMS provides assurance that all ASTM required measurements are conducted at the appropriate time and will send a signal or message to the control system if a validation issue is encountered. Learn more about SMS.