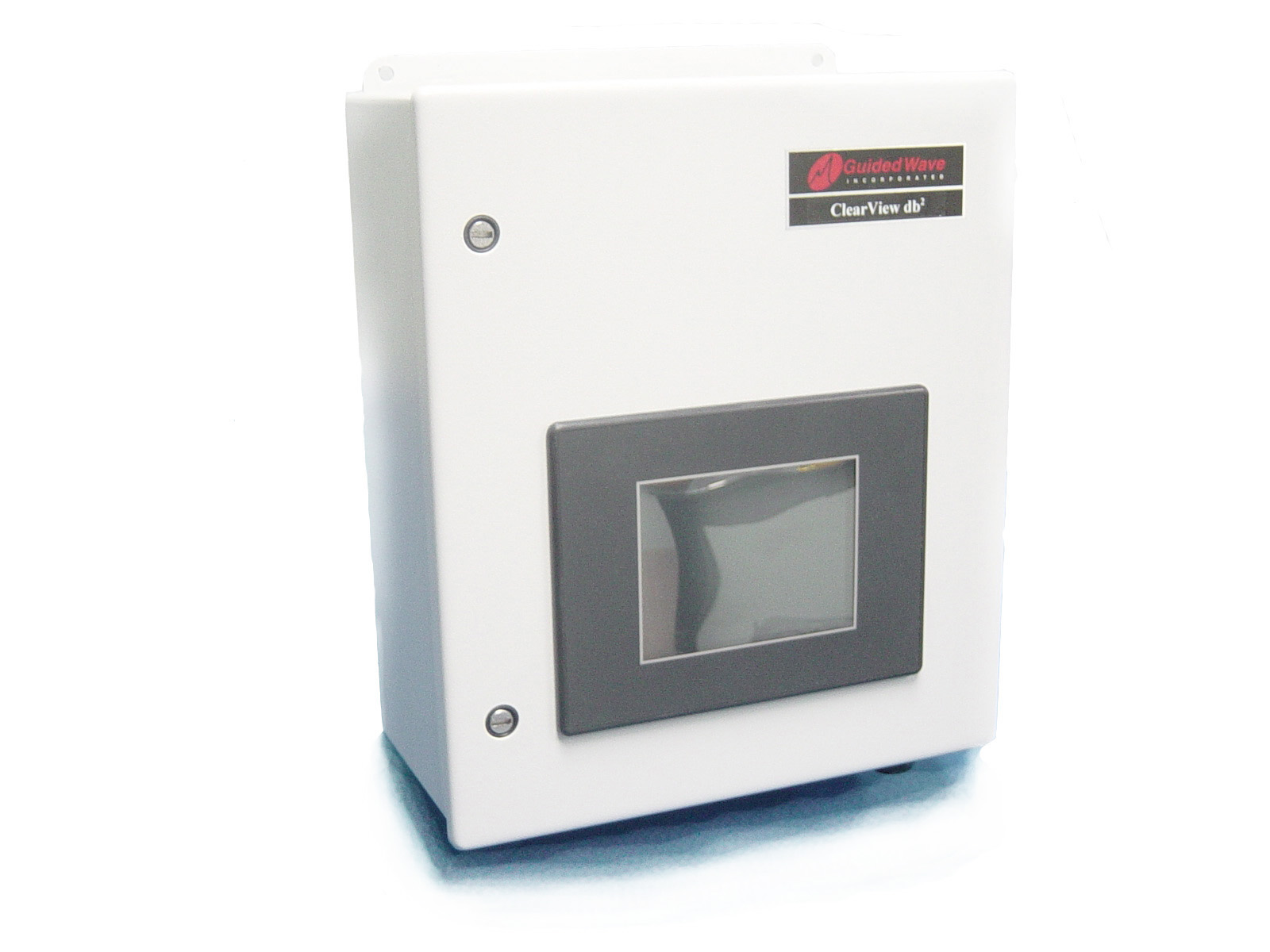

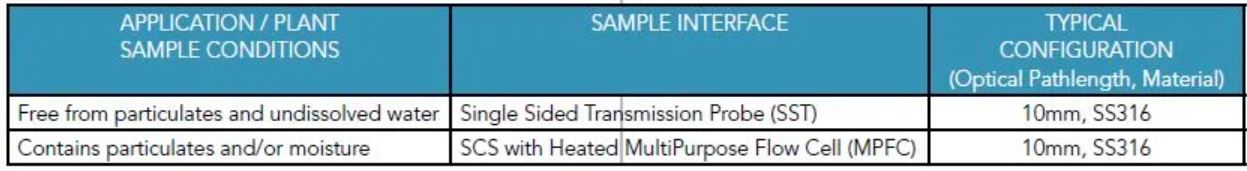

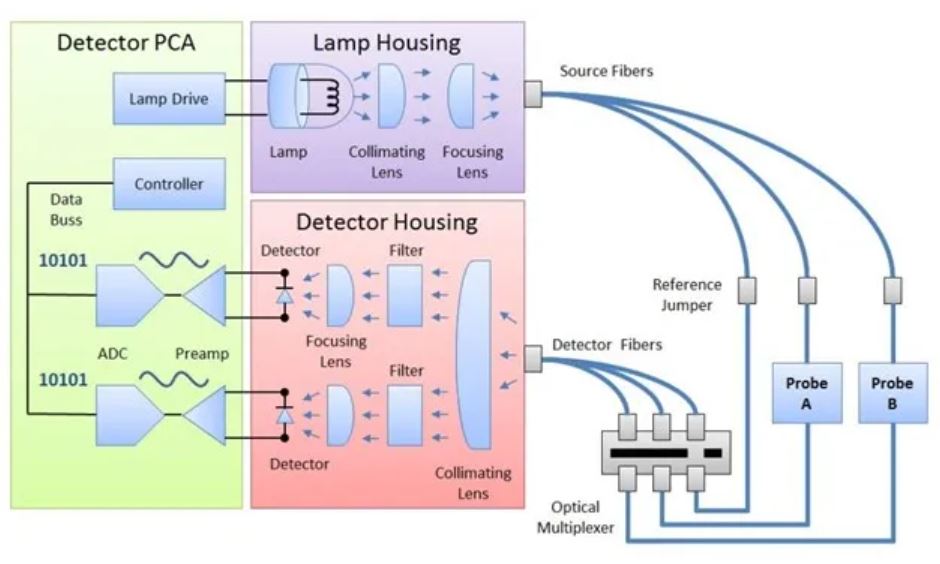

For example, terephthalic acid (TPA) and dimethyl terephthalic acid (DMT) can both be synthesized by reacting P-xylene with cobalt–manganese–bromide catalyst, acetic acid, and air. Realtime quantitative monitoring of this caustic reaction is possible with the Guided Wave ClearView db analyzer along with an SST probe. The SST probe can be installed directly into the reaction vessel for continuous process monitoring and optimization. Additionally, in an extremely corrosive environment, the sample probe can be constructed out of Hastelloy C276.

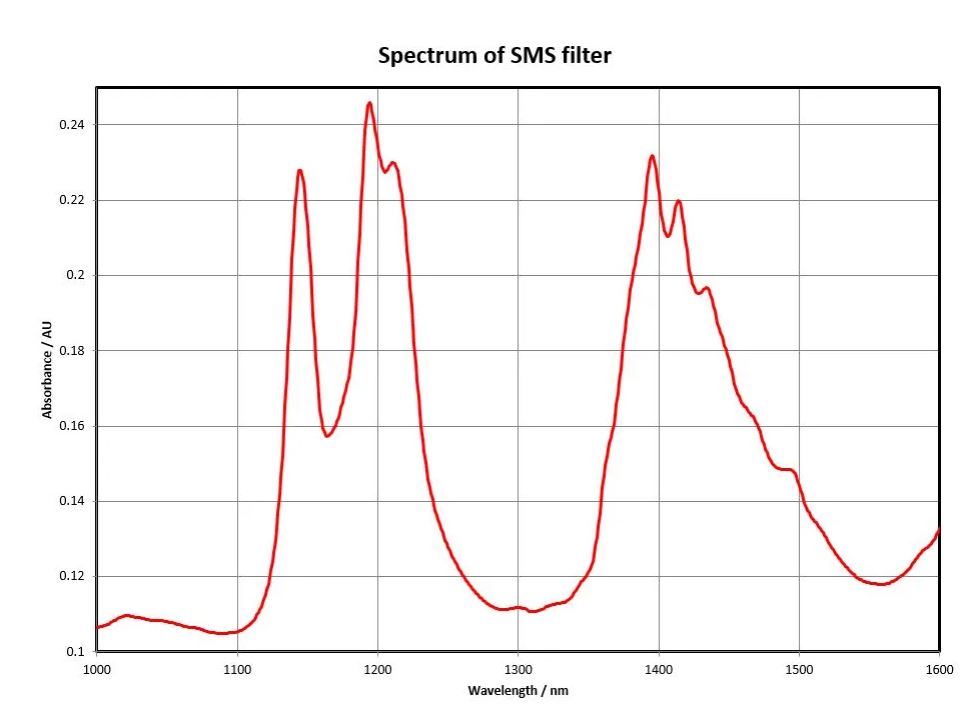

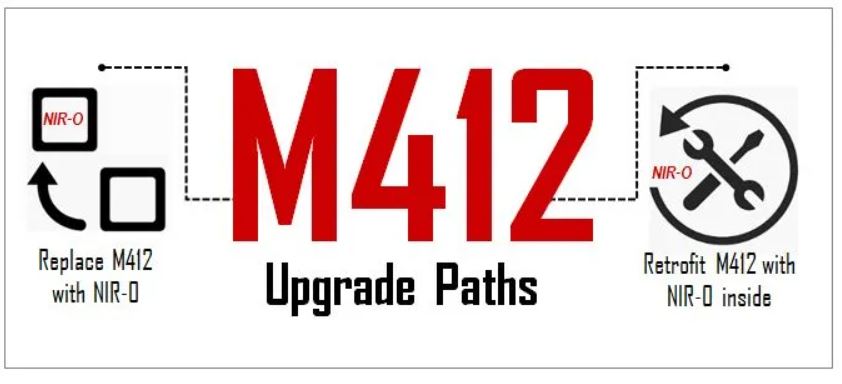

In batch polymerization, DMT reacts with ethylene glycol in esterification to form monomer alcohol, which then polymerizes with TPA. The continuous method, on the other hand, involves a polymerization between TPA and ethylene glycol, so DMT is not necessary. Both methods involve heating either DMT or TPA with ethylene glycol to about 536 ºF for 30 minutes at atmospheric pressure, and then the mixture spends 10 hours under vacuum. near-infrared analyzers such as the ClearView db and NIR-O Process analyzers can be used to provide in-situ monitoring of the cross-linking under vacuum conditions. Out of specification product can be detected with a high temperature shuttle probe and near-infrared monitoring during melt transfer. By monitoring the molten polymer stream for acid number, cost savings can be realized by preventing the off-spec product from reaching the extrusion or pelletizer.

Rugged sample interface designs built to withstand harsh polymer process conditions, as well as the low maintenance requirements make Guided Wave probes and flow cells a cost effective, smart choice to help optimize polymer production, improve yields, ensure consistent product quality and enhance profitability. While Guided Wave’s probes and flow cells are optically matched for use with Guided Wave NIR or UV-VIS analyzers to provide top system performance, they are also compatible with many other analyzer brands.